A company that pursues innovation.

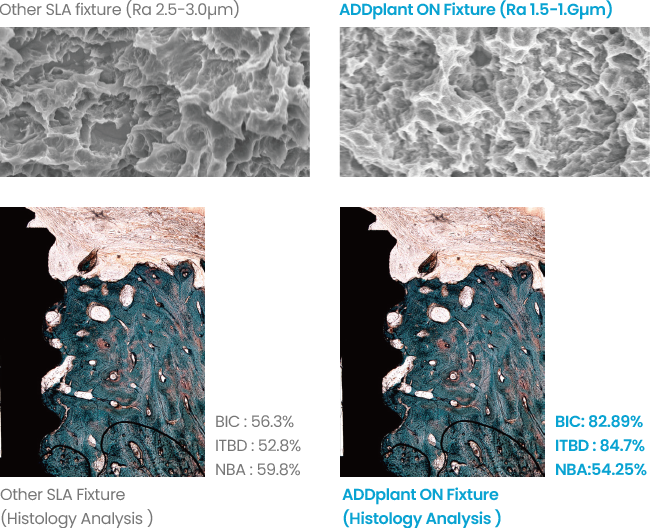

Implants with a special SLA surface, manufactured and processed without impurities and less roughness.

E-Catalog View

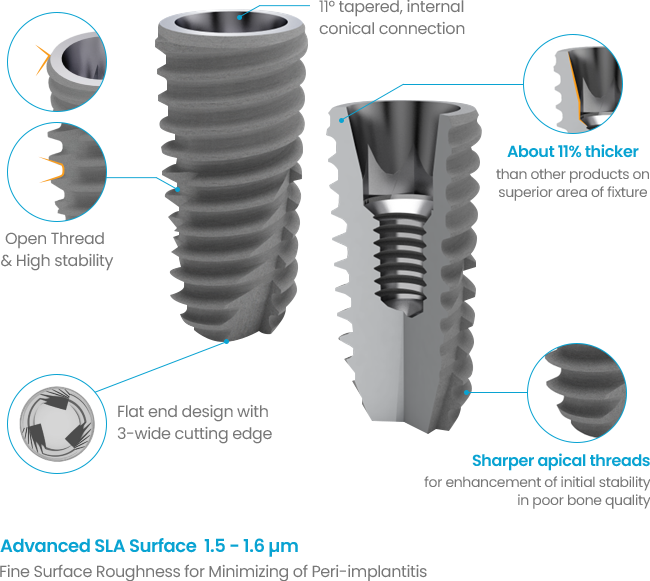

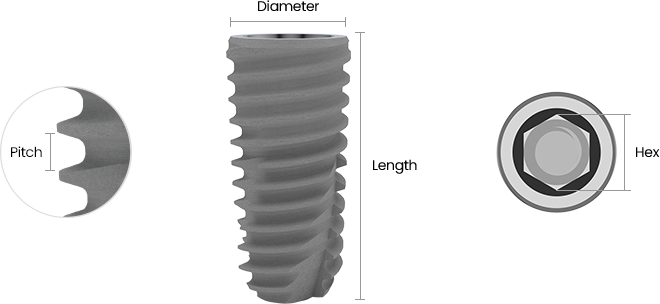

Intimate engagement with the abutment by the inner design of the 11° Morse taper Double-threaded and tapered body design for quick implant placement Minimize fixture fracture by self-tapping a 3-wide cutting edge

Roughly 11% thicker than other implant fixtures at the abutment interface Grade 4 titanium provides excellent corrosion and fatigue resistance, as well as high strength

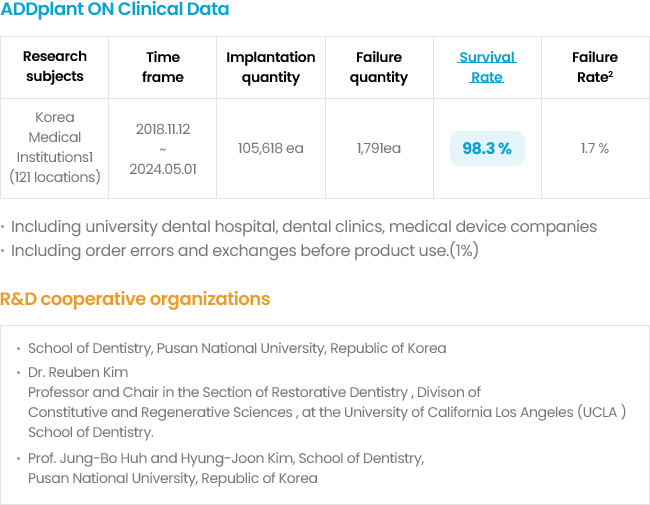

Great bone response in big animals study (mandibular pen-implant dehiscence defect model in Beagle dogs) Optimal fine surface roughness for reducing bacterial adhesion, minimizing Peri-implantitis Proved uniform cell adhesion in cell proliferation tests using CCK-8 assay

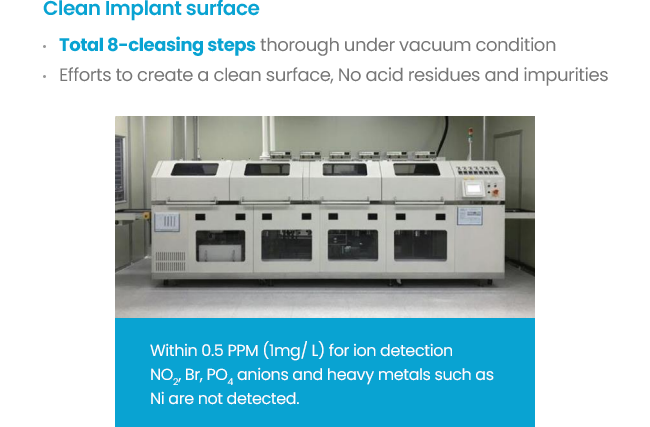

Clean implant surfaces free of acid residues and impurities through an 8-step cleaning process under vacuum Within 0.5 PPM (1 mg/L) for ion detection NO2, BR, PO4 anions and heavy metals such as Ni are not detectable in residual ion detection analysis (IC/ICP)

| L |

|

|

|

|

|

|

|

| 7.0mm | - | ASR4007NS | ASR4507NS | ASR5007NS | ASR5507NS | ASW6007NS | ASW7007NS |

|---|---|---|---|---|---|---|---|

| 8.5mm | ASM3508N | ASR4008NS | ASR4508NS | ASR5008NS | ASR5508NS | ASW6008NS | ASW7008NS |

| 10mm | ASM3510N | ASR4010NS | ASR4510NS | ASR5010NS | ASR5510NS | ASW6010NS | ASW7010NS |

| 11.5mm | ASM3511N | ASR4011NS | ASR4511NS | ASR5011NS | ASR5511NS | ASW6011NS | ASW7011NS |

| 13mm | ASM3513N | ASR4013NS | ASR4513NS | ASR5013NS | ASR5513NS | ASW6013NS | ASW7013NS |